Prof. Henrik von Scheel on what’s next for machinery manufacturers

Recognized by CNBC as one of the century’s most influential futurists, Prof. Henrik von Scheel will be speaking at our Machinery Megatrends Webinar next month. As we await his session, we sat down to talk about the eight-stage evolution shaping manufacturing, where B2B teams are still underestimating risk, and why ERP-connected commerce is now the operating backbone, not a nice-to-have.

He’ll also share an early look at the next TrendRadar before it hits the market, plus practical moves you can take straight to your board.

- What’s changing fastest for machinery manufacturers right now?

- Where are B2B organizations still underestimating risk, or opportunity, when it comes to digital transformation?

- Why does ERP-connected commerce matter so much now?

- What role do ERP-connected systems play in Industry 4.0?

- About Prof. Henrik Von Scheel

- Join the webinar: Megatrends reshaping machinery manufacturing

What’s changing fastest for machinery manufacturers right now?

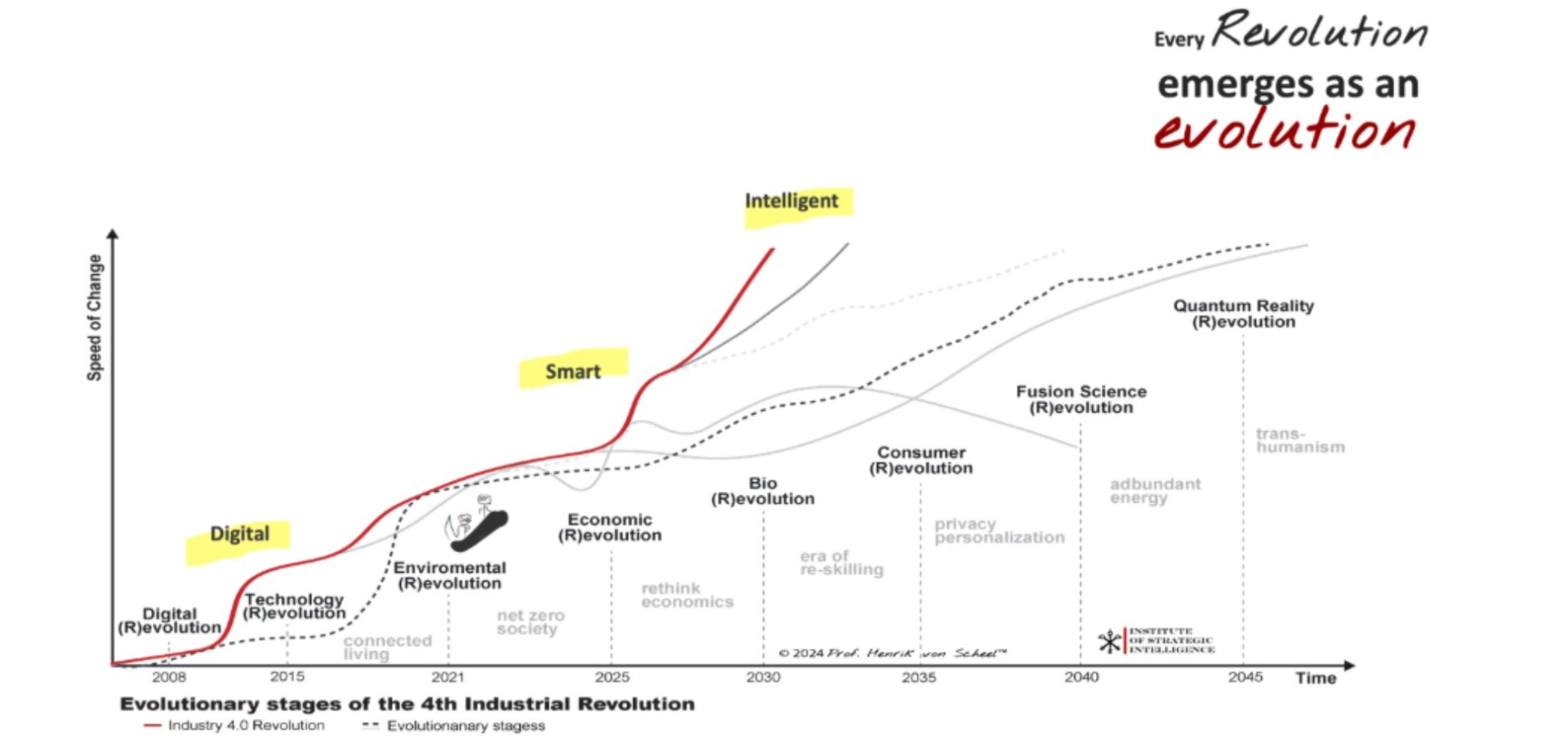

Henrik: We’re in an evolution, not a single “big bang.” Industry 4.0 unfolds in eight stages, driven by dozens of megatrends, reshaping how we design, make, sell and service until at least 2050. Today, we’re in stage four.

For manufacturers, the near-term priorities cluster around three buckets: productivity (Digital 2.0, Factory 4.0, collaborative intelligence, smart automation, industrial AI), resilience (sustainable operations, Risk Management 4.0, predictive intelligence, stronger ecosystems, future-of-work), and growth (profit from sustainability, customer centricity, financial re-engineering, sourcing autonomy, operate-to-grow).

Where are B2B organizations still underestimating risk, or opportunity, when it comes to digital transformation?

Henrik: Honestly, I see the same misses over and over. Just a couple of top tips:

- We still treat digital like a tools purchase, when the real job is redesigning how the business runs and decides day to day.

- We tick the box with process maps, but what moves the needle are event-driven, cross-functional workflows that adapt in real time.

- We launch “big transformation programs” that freeze up when things change, instead of shipping value in short, composable sprints.

- We automate yesterday’s tasks instead of asking which tasks should exist at all.

- We hand the change to IT, when it must be owned by business with IT as the enabler.

- We keep commerce and ERP at arm’s length and end up selling blind; connect them and what you promise is what you deliver.

Why does ERP-connected commerce matter so much now?

Henrik: ERP systems govern the core logic of your business—inventory, pricing, customer terms, lead times. If your commerce layer is disconnected, you are essentially selling blindfolded. Integration with ERP ensures that what you promise to the customer is what you can actually deliver—in real time, at scale, and with precision.

In my work with global manufacturers and B2B leaders, I’ve consistently seen that ERP-commerce integration multiplies the value of both systems—accelerating fulfilment, reducing errors, and unlocking trust. It's not an IT feature, it’s a strategic enabler of competitiveness.

What role do ERP-connected systems play in Industry 4.0?

Henrik: They’re the operating backbone where real-time signals turn into coordinated decisions. It brings orders, inventory, pricing, lead times, and financials into one source of truth so sales, supply chain, service, and finance act on the same data. By linking the shop floor to the top floor, it keeps production changes aligned with plans and customer promises.

In practice, that looks like a sensor flagging a spindle issue, your ERP raising a work order, checking parts and skills, reshuffling the plan, placing a purchase with the right supplier, and updating available-to-promise so your portal reflects the new delivery date in minutes instead of days. The bottom line is in Industry 4.0, your ERP isn’t a ledger; it’s the real-time control center that keeps plans, operations, and promises in sync.

About Prof. Henrik Von Scheel

Prof. von Scheel helped ignite the digital and Industry 4.0 themes and co-founded Strategic Intelligence, which has set the agenda for the World Economic Forum and others over the past two decades. He has co-authored 153 Business, Architecture and IT standards influencing 24 national economies and a significant share of the Fortune 500 and advises on EU policy including the AI Act and climate frameworks (Green Deal, Fit for 55, CBAM).

The Financial Times calls him a leading authority on strategy.

Join the webinar: Megatrends reshaping machinery manufacturing

Get a first look at the next TrendRadar before it’s public, understand where you sit on the Industry 4.0 curve, and see how leaders use real-time spare-parts portals to cut friction and grow ARR.

You’ll leave with a practical plan to keep machines running and revenue flowing.

Seats fill fast. Book yours now.

Psst: registrants can enter to win the LEGO® Technic Volvo FMX Truck & EC230 Electric Excavator!

Editor’s note: This interview has been condensed for clarity. Many thanks to Prof. Henrik von Scheel for his insights.

Solve the B2B buying puzzle with Sana Commerce

Solve the B2B buying puzzle with Sana Commerce

Watch how Sana Commerce Cloud transforms businesses like yours.

More interesting resources

More interesting resources